Industrial insulation is central to modern facilities. Without the right materials, heat loss, moisture intrusion, and fire risk all undermine performance. Selecting the right industrial insulation types ensures long-term efficiency and reliable protection across entire systems.

8 Common Industrial Insulation Types

Applications vary by temperature, chemical exposure, and physical stress, so no single solution works everywhere. Engineers weigh cost, service life, and code compliance before choosing a system. The following categories outline the primary industrial insulation types used in facilities worldwide.

1. Fiberglass Insulation

Fiberglass is produced by spinning molten glass into fibers and forming them into batts, blankets, or loose fill. It handles moderate temperatures, typically up to ~450 °F, making it a common wrap for ducts and equipment. Its non-combustible makeup supports fire safety, though it must be protected from moisture that quickly reduces effectiveness. Among the industrial insulation types, fiberglass stands out for its low cost and wide availability. Simple, reliable, and widely available.

2. Mineral Wool

Mineral wool, also called rock wool or slag wool, is formed by melting stone or furnace slag and spinning it into dense fibers. It withstands far higher temperatures than fiberglass and absorbs sound in noisy facilities. While heavier and more expensive to install, it endures for decades under tough service. That durability explains why engineers still rely on it near boilers and furnaces.

3. Rigid Foam Panels

Expanded polystyrene (EPS) and extruded polystyrene (XPS) are the most common rigid foams. Both deliver strong R-values per inch and resist water absorption, which is why they appear in walls, roofs, and below-grade assemblies. Easy to cut and cost-effective, these foams fill an important role—but they cannot tolerate the high service temperatures that mineral wool or refractory products withstand.

Polyiso

Polyisocyanurate, or polyiso, offers one of the highest R-values per inch of any foam. It combines thermal efficiency with compressive strength, making it the backbone of continuous insulation assemblies and roofing systems. Boards are rated for service between −100 °F and 250 °F, depending on facer type and product specification. With a closed-cell structure that resists moisture and a fire profile that supports code compliance, polyiso strikes a balance of efficiency, safety, and long-term durability. It’s why this material anchors so many industrial assemblies.

4. Spray Foam

Spray foam delivers air sealing and thermal control in one step. Closed-cell polyurethane formulations expand to fill voids and lock onto substrates, creating continuous coverage that panels or blankets can’t match. That makes it ideal for tanks, vessels, and penetrations with irregular geometry. While it costs more and requires skilled applicators, its ability to seal irregular assemblies makes it a practical choice for demanding industrial projects.

5. Ceramic Fiber

Ceramic fiber, or refractory insulation, is manufactured from alumina and silica and withstands service temperatures of 2,300–2,600 °F. It is indispensable in kilns, furnaces, and exhaust systems where no other material holds up as well. Lightweight with low thermal conductivity, it resists heat but can fracture under mechanical stress. Installers must protect against fiber release, yet it remains one of the few industrial insulation types capable of surviving extreme heat without loss of performance.

6. Calcium Silicate and Microporous Insulation

Calcium silicate is a rigid, high-strength insulation rated for service up to 1,200 °F. It’s commonly applied on steam lines, vessels, and equipment surfaces where both mechanical durability and thermal performance are required. Microporous insulation takes a different approach, using ultra-low conductivity in thin profiles to deliver high efficiency where space is limited. Both come at a premium, yet their long service life and resilience under demanding conditions justify the investment. In mission-critical systems, they provide the safety margin engineers count on.

7. Aerogel and Vacuum Insulation Panels

Aerogel is a porous silica structure that combines ultralight weight with extremely low thermal conductivity. Vacuum insulation panels (VIPs) achieve similar results by eliminating conductive and convective transfer through an evacuated core. Both deliver unmatched R-values per inch, which makes them invaluable when space is at a premium or equipment requires maximum efficiency. They are fragile and costly, limiting their use to specialized projects. Even so, when performance is non-negotiable, aerogel and VIPs provide solutions other materials cannot.

8. Reflective and Radiant Barriers

Reflective insulation and radiant barriers redirect radiant heat away from equipment and surfaces with thin layers of aluminum foil or metallized film. Their conductive R-values are low, but in spaces dominated by radiant loads they make a measurable difference. Lightweight and easy to install, they require an air gap to work properly. Rarely used alone, reflective barriers often supplement other assemblies to improve overall performance.

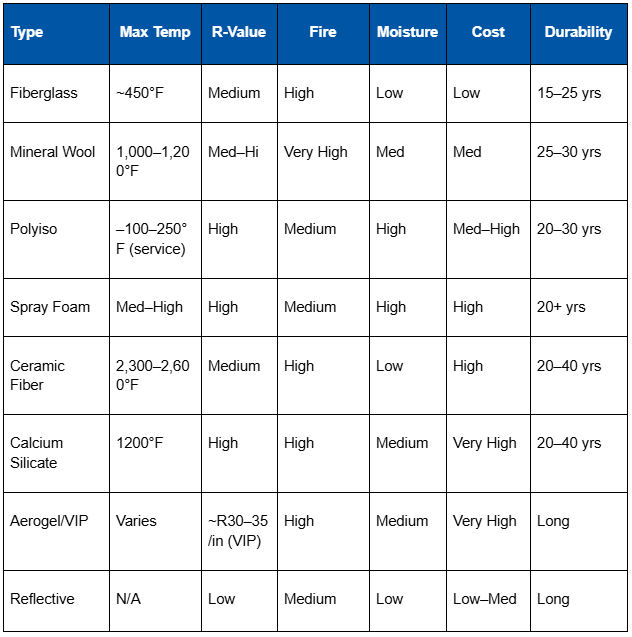

Comparing Industrial Insulation Materials

A side-by-side comparison makes it easier to weigh performance, cost, and service life.

Key Factors in Choosing Insulation

Several performance factors determine which insulation material fits an application best.

Temperature and Service Range

Temperature is usually the first filter. Facilities running at hundreds of degrees need mineral wool, ceramic fiber, or calcium silicate. For moderate service, fiberglass and polyiso are appropriate. Polyiso is widely used in continuous insulation assemblies for commercial projects, where commercial insulation types drive energy efficiency and code compliance.

Moisture and Chemical Exposure

Wet or corrosive conditions require materials that resist water absorption and chemical breakdown. Closed-cell foams and treated mineral wool maintain integrity even in steam-heavy or aggressive service environments.

Fire and Safety Codes

Many industrial codes demand non-combustible materials or verified fire ratings. Standards such as ASTM E84 (surface burning characteristics) and EN 13501 (European fire classification) establish the benchmarks that products must meet. Mineral wool, ceramic fiber, and calcium silicate all provide proven performance under these tests, making them reliable options where fire resistance is key. Polyiso, when used with proper facers and coverings, also contributes to assemblies designed to meet these requirements.

Lifecycle Cost and Durability

Initial price does not always equal value. Fiberglass may seem economical, but repeated replacements and energy losses add hidden costs. Higher-priced options extend service life and reduce maintenance cycles, improving return on investment. Awareness of the available industrial insulation types ensures better decisions across a facility’s lifecycle.

Innovations and Trends in Industrial Insulation Products

The industry continues to push insulation toward greater efficiency and sustainability.

Bio-Based Foams

Foams derived from renewable feedstocks reduce reliance on petrochemicals while meeting established performance standards. They offer lower environmental impact without sacrificing reliability.

Smart Monitoring Systems

New systems embed sensors that track temperature, moisture, and integrity in real time. They provide early warning of failures so operators can respond before small issues grow into costly downtime.

Vacuum Insulation Panels

Once reserved for aerospace, vacuum insulation panels are now being used in advanced manufacturing and energy storage. Their extremely low thermal conductivity makes them ideal where space is tight and efficiency demands are high.

Together, these developments point toward a new generation of industrial insulation types that combine advanced performance with smarter, more adaptable systems.

Smarter Insulation Choices Start with Rmax

Rmax manufactures insulation systems engineered for energy efficiency, durability, and compliance across commercial and industrial applications. Our products are designed to reduce operating costs, extend service life, and simplify installation in demanding environments. Contact us today for more information.