Polyiso vs. Mineral Wool

Rmax insulation has been designed and tested to provide building envelopes with superior insulating protection while meeting the fire requirements of building codes, including numerous NFPA 285 assemblies.

Rmax’s engineered products and solutions allow for ultimate efficiency through multiple design options, creating ease of construction and reduced energy usage. This leads to a better building envelope while adding to the bottom-line through both material and labor savings - making Rmax an excellent choice for commercial buildings.

Water Absorption

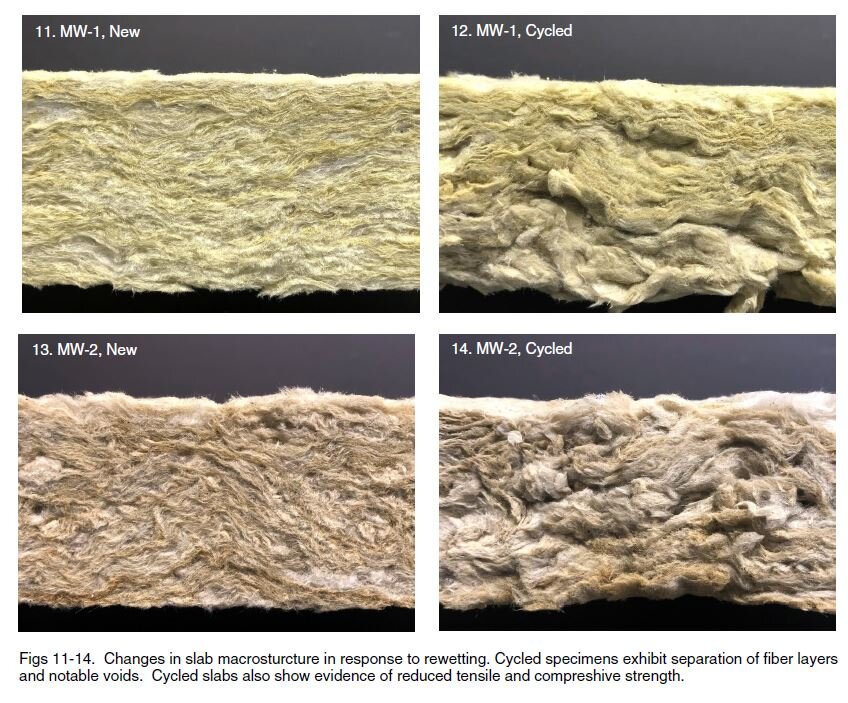

Wetting behaviors of common insulation products were assessed by standard two-hour water immersion. Mineral wool slabs absorbed 8 to 38 times more water than foil-faced polyisocyanurate (PIR) and 4 to 19 times more water than coated glass-faced PIR. Drying within vented benchtop assemblies required 2 to 6 days longer for mineral wool as compared to PIR. Rewetting of mineral wool specimens increased water absorption by 130% to 190% and extended dry times by an additional four days. In comparison, sorption behaviors of PIR remained unchanged. Repeated wetting of mineral wool revealed dynamic holding capacities that varied on the basis of pore structure and slab macrostructure.

Figs 11-14. Changes in slab macrosturcture in response to rewetting. Cycled specimens exhibit separation of fiber layers and notable voids. Cycled slabs also show evidence of reduced tensile and compreshive strength.

Check out the Comparative Study of Water Absorption, Drying and Rewetting by M. Steven Doggett, Ph.D., Principal Scientist & CEO of Built Environments for more information.

COMPRESSIVE STRENGTH

With 2 ½ times the compressive strength, Rmax Polyiso can support heavy cladding weight, while mineral wool requires highly conductive and costly Z-Furring, hat channels or proprietary clip systems.

Mineral wool manufacturers often list compressive strength values in pounds per square foot (psf) and allow greater deformation during the test - misleading one to think they have high values. When converting psf to psi and using the same test method as Polyiso, mineral wool provides less than half of the compressive strength of standard Polyiso. Lack of compressive strength requires complex, cumbersome and costly cladding attachment systems which reduce effective R-values through thermal bridging.

Why Polyiso is the better choice

Higher Thermal Performance

Greater Compressive Strength

Withstands "Wind-Washing" Effects

Eliminates Thermal Bridging - Does Not Require Cladding Attachments

More Environmentally-Friendly

Significantly Outperforms in ASTM C209 Water Absorption Testing